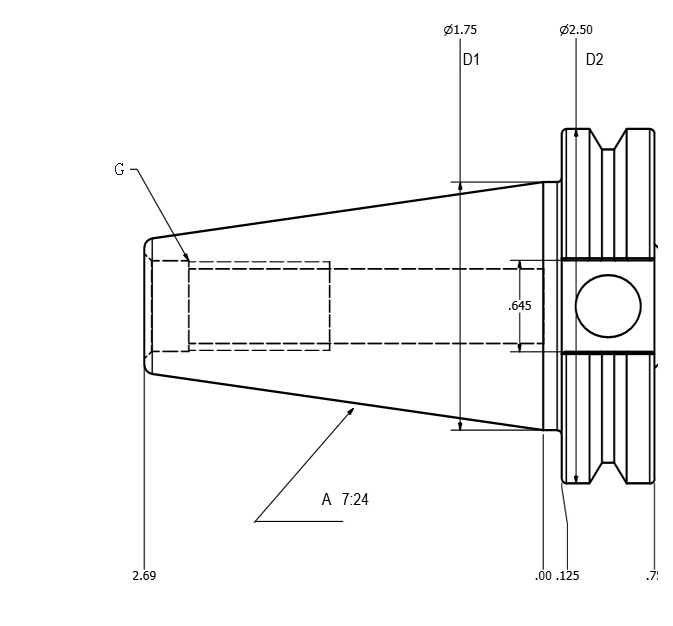

- BT40 Drill Chuck Tool Holders

- Works on all BT40 machines

- Clamping Size: 1/2 and 5/8

- All critical surfaces precision ground

- Made from alloy steel hardened to 54 – 56rc

- Gage length is: 4inches

- Concentricity is less than .005 at collet face

- Rear thread for pull stud is M16x2

- Color Silver Coated: never rusty ever

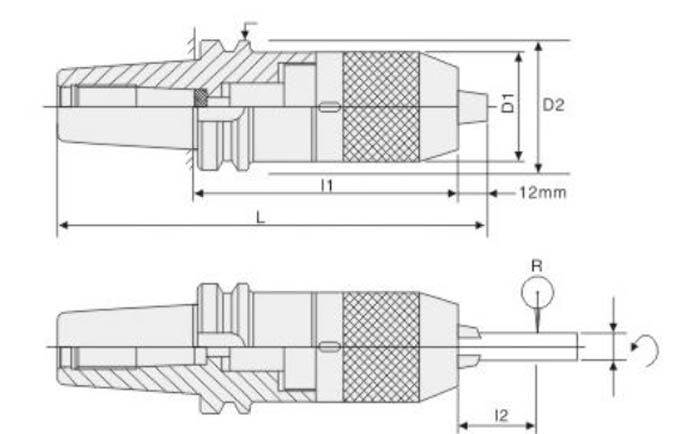

BT40 Integrated Drill Chuck Tool Holders keyless Chuck

Description

BT40 Integrated Drill Chuck Tool Holders Keyless Chuck

Why choose to keyless drill chuck tool holders

The compact drill chuck adopts the self-tightening function of the self-tightening drill chuck in structure. With the wrench,

the clamping jaw of the hand-tight drill chuck is cylindrical. And avoiding its shortcomings and processing difficulties

1. High precision and quick clamping;

2. With self-tightening function, you can just clamp the drill bit gently, and increase the clamping force synchronously with the increase of the torque in the drilling,

and can produce a noticeable high-strength clamping force to prevent the drill bit from slipping;

3. Heat treatment for clamping jaw HRC55

4. Taper holes can be used with drill shanks of various specifications

5. All parts and taper with silver coated never rusty ever

6. Using in automatic operation controlled by computer management process withprocessed safely and smoothly

|

Drill Chuck Tool Holders |

||

|---|---|---|

| BT0 | Product NO. | BT40 Integrated Keyless Drilling Chuck Tool Holder 13MM |

| Insulation material | Hardened Alloy Steel | |

| Clamping Range | 2-13mm or 3/32″ to 1/2 “ | |

| Run Out (TIR) | <0.001″ or 0.03mm | |

| Color | Silver Coated | |

| Standard Spindle | BT40 Taper | |

| Stop Screw | Threaded for internal stop screw included | |

| Manufacture | IGSTOOL | |

Application Guide ANSI BT Taper Standard

BT40 Integrated Keyless Drill Chuck Tool Holder

All critical tool holder surfaces precision ground with silver coated

BT40 Drill chucks are mainly hand drill chucks and keyless drill chuck tool holder.

The drill chuck by ahankd are mostly produced by machine tools in large quantities, so the price is cheap,

but due to the limitation of its structure, the accuracy of the wrench drill chuck is not high.

It is mainly used for bench drills, small radial drills, power tools Where clamping accuracy is not high,

the drill bit needs to be tightened with a wrench, and the operation is more complicated. In machining centers,

advanced drilling machines and other places that require high drilling accuracy, keyless drill chucks tool holder are generally require