- Straight Shank 3/4 ER16 Floating Tap Tool Holder Tapping Chuck

- For ER20 and ER16

- Shank available. 3/4 ,1″,16mm 20mm

- Threaded for stop screw ( included)

- All critical surfaces precision ground

- Made from alloy steel hardened to 54 – 56rc

- Collet nut is included

- Color: oxide and anodizing

Straight Shank 3/4 ER16 Floating Tap Tool Holder Tapping Chuck

Description

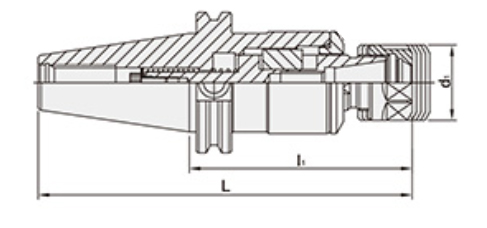

C3/4 ER16 Floating Tap Tool Holder Tapping Chuck

The IGSTOOL Face Mill Tool holder is balanced to G2.5 25,000 RPM on Germany HAIMER Tool Dynamic Balancing System,

Each Tool Holder with QC report card. 100% guarantee of each tool holder in the high-performance

A balanced tool holder minimizes the centrifugal forces which minimize the stress on spindle bearing,

minimize vibration and maximize the cutting tool’s life cycle and greatly improve surface finish

We accept Custom OEM Order

Specification

C3/4 ER16 Floating Tap Tool Holder Tapping Chuck |

||

|---|---|---|

| Straight shank | Product NO. | Floating tap tool holder IGST001 |

| Insulation material | Hardened Alloy Steel | |

| Collet available | ER32,ER25,ER20 ,ER16 and ER11 | |

| Run Out (TIR) | <0.005″ or 0.05mm | |

| Color | Oxide and anodizing | |

| Standard Size available | 20mm,16mm 1″, 3/4 ,1/2 | |

| Compression and Extension | 10mm | |

| Manufacture | IGSTOOL | |

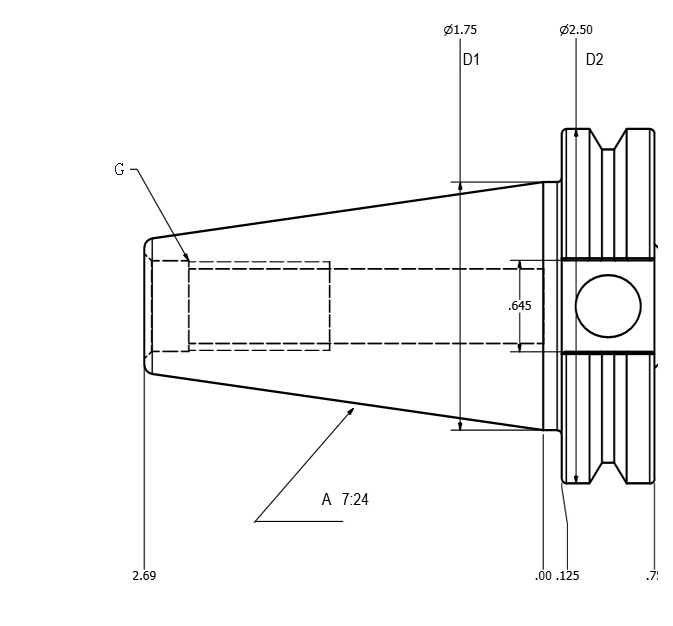

Application Guide CAT Spidle Size

What is a Floating tapping tool holder?

The floating tapping tool holder is a device with a spring inside, which is used for flexible tapping, also called floating tapping.

It can be used on automatic working machine tools, multi-axis tapping machines, and CNC machining centers without synchronous tapping.

When tapping with a lathe or a tapping machine, whenever the depth has reached the set value, the tap is broken due to inertia or due to machine control tolerances.

This phenomenon is particularly prominent when tapping the blind hole thread. With the telescopic compensation tapping tool holder, the flexibility of the tool holder can be used to protect the tap and prevent the tap from breaking when the thread is tapped to the end of the length of the main shaft drop is too large.

When the thread is reversed after tapping, in order to prevent the thread from being damaged when the spindle is reversed, the retractable tapping tool holder also provides compensation in the stretching direction and also relieves the force on the tap when the spindle is first reversed, reducing the tap. Damage to extend the life of the tap.Straight Shank 3/4 ER16 Floating Tap Tool Holder Tapping Chuck