CNC TOOL HOLDERS TAPER STANDARD IN THIS WORLD

At present, the main market has 7/24 and 1/10 taper shank holders, of which 7/24 has numerical control and general use, and numerical control has international standards, Germany, Japan, and the United States. A common use is a distinction between metric and inch systems.

In the Chinese market, the Japanese BT type is used the most, the American market uses ANSI and ASME, and the German DIN69871 (SK or NC), 1/10 taper shank because of its cost and manufacturing technology problems, there are few domestic companies Can do it, its model uses HSK machine spindle requirements are relatively high, domestic manufacturers have not universally used,

Among the manufacturing companies of tool holders, the BBT of Japan’s BIG company can replace HSK because HSK is a hollow handle and there is a problem with the structural strength, but BBT is different. And over-positioning (HSK, BIG, etc.), the static accuracy is good, the main difference is the dynamic accuracy.

It is said that HSK, etc. can still maintain the tightness of contact with the spindle at high speed, and the dynamic accuracy is good, because it is widely used in high-speed processing.)

Most of BT and HSK transmit torque through keys, and some tool holders transmit torque through their shapes (such as the Capto interface).

Tool holders that generally transmit torque through their shape are said to transmit larger and more stable torque, especially at high speeds.

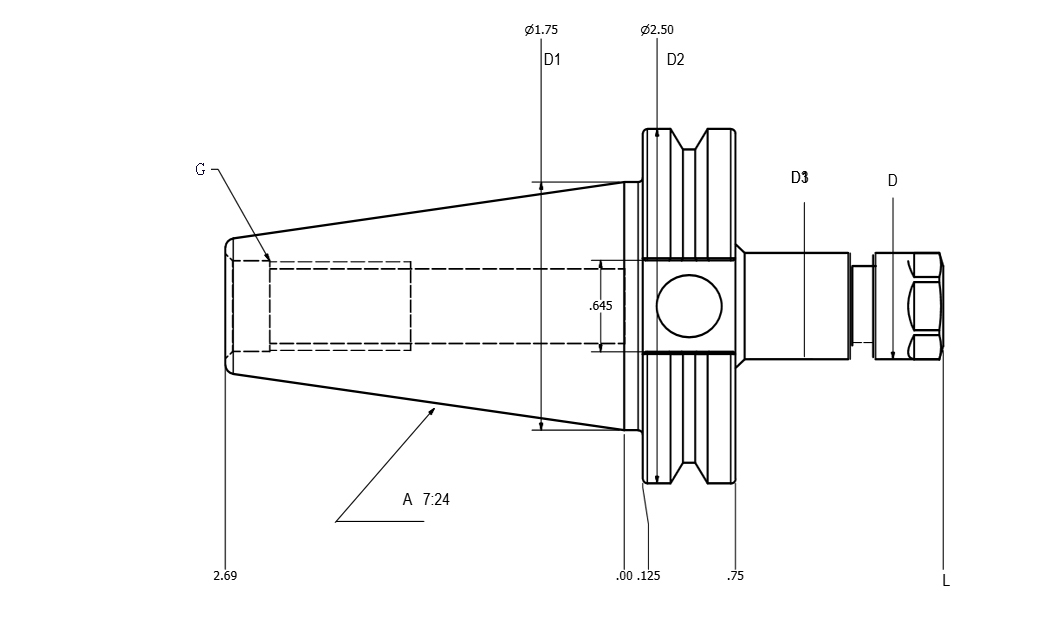

The taper holes of the spindle of a machining center are usually divided into two categories, that is, a universal system with a taper of 7:24 and a HSK vacuum system of 1:10.

Universal tool holders with a taper of 7:24 usually come in five standards and specifications,

That is NT (traditional), DIN 69871 (German standard), IS0 7388/1 (international standard), MAS BT (Japanese standard), and ANSI / ASME (American standard).

The German standard for NT tool holders is DIN 2080, which is used to tighten the tool holders on the traditional machine tools through pull rods. It is also called ST in China;

The other four tool holders are tightened on the machining center by the studs at the tail of the tool holder.

At present, the most widely used tools in China are DIN 69871 (JT) and MAS BT.

DIN 69871 tool holders can be mounted on DIN 69871 and ANSI / ASME spindle taper bore machines,

Tool holders type IS0 7388/1 can be mounted on machines with DIN 69871, IS0 7388/1 and ANSI / ASME spindle taper holes.

So in terms of versatility, the IS0 7388/1 tool holder is the best.

CAT Tool Holders Standards Size follwing