- BT40 Face Mill Tool Holder

- Works on all BT40 machines

- From 16mm to 50mm

- All critical surfaces precision ground

- Made from alloy steel hardened to 54 – 56rc

- Balanced to G2.5 at 25,000 RPMs

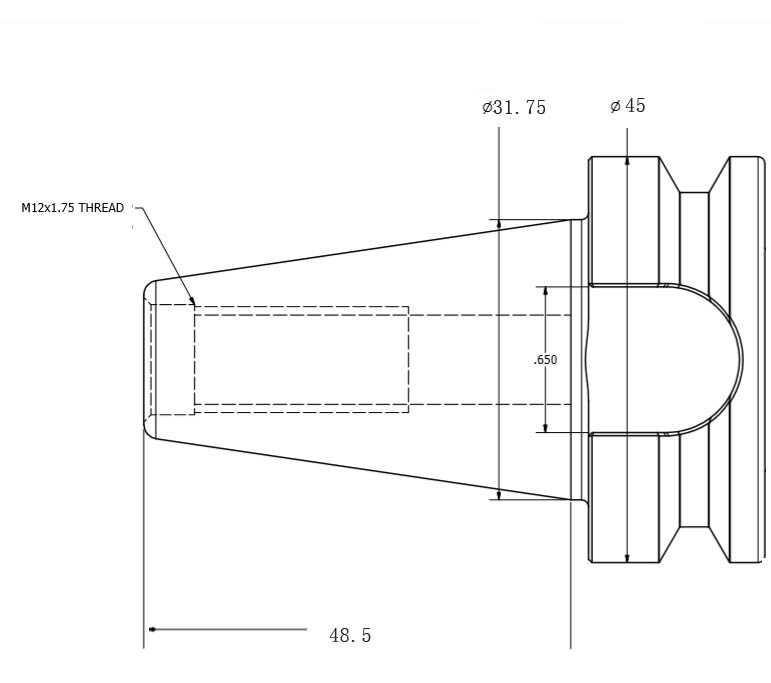

- Gage length is ( from 0.5″ to 8 inches)

- Concentricity is less than .0001 at collet face

- Screw include

- Rear thread for pull stud is M16x2

- Color: oxide black

BT40 Face Mill Tool Holder Shell Mill Arbor

Description

BT40 Face Mill Tool Holder Shell Mill Arbor

The IGSTOOL Tool holder is balanced to G2.5 25,000 RPM on Germany HAIMER Tool Dynamic Balancing System,

Each Tool Holder with QC report card. 100% guarantee of each tool holders in the high-performance

Balanced tool holder minimizes the centrifugal forces which minimize the stress on spindle bearing,

minimize vibration and maximize the cutting tool’s life a long time and greatly improve surface finish

We accept Custom OEM Order

Specification

Face Mill Tool Holder |

||

|---|---|---|

| BT40 | Size available | 3/4 to 2″ or 16mm to 50mm |

| Insulation material | Hardened Alloy Steel | |

| Hardness | HRC 55 | |

| Run Out (TIR) | <0.0002″ or 0.005mm | |

| Color | Oxide Black | |

| Standard Spindle | BT40 Taper | |

| Stop Screw | yes | |

| Manufacture | IGSTOOL | |

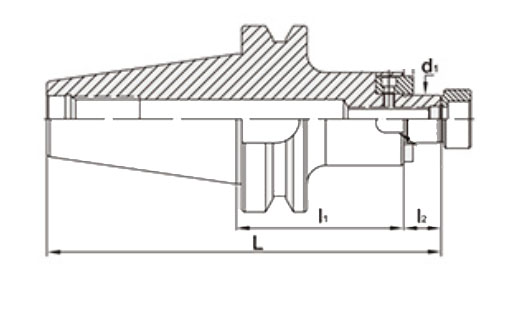

BT40 Taper Application Guide

BT40 Face Mill Tool Holder

BT Face Mill Tool Holder series for face milling cutter. The whole through-hole is good for the water outlet and has good shock resistance. Material: Titanium alloy 20CrMnTi is used, which has good elasticity and wear resistance after heat treatment, high precision, wear-resistance, and durability. The tool holder has a hardness of 52-55 degrees, low noise, small wind resistance, and high accuracy of repeated clamping. Mainly used for tool holder and tool holding in drilling, milling, reaming, tapping and grinding