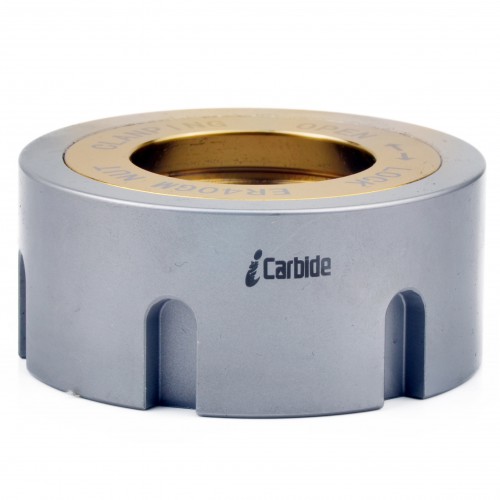

- ER40 Tool Holder Collet Nut

- All critical surfaces precision ground

- Made from alloy steel hardened to 54 – 56rc

- Thru twice heat treatment of each collet nut

- Balance :G2.5 25000rpm

- Color :oxide black

ER40 Tool Holder Collet Nut Balance Designed

Description

ER40 Balanced G2.5 25000rpm Tool Holder Collet Nut

Designed base in balance G2.5 25000rpm approved excellent quality.

CNC Machining Groove slot in order easy takeoff ER collet from the tool holder body

We accept Custom OEM Order

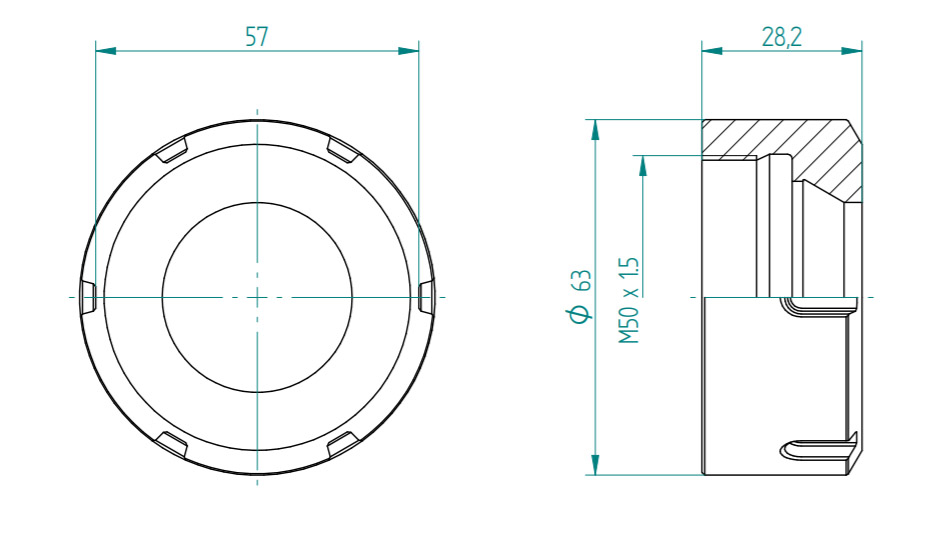

Tool Holder Collet Nut |

||

|---|---|---|

| ER40 | Product NO. | ER40 Collet Nut |

| Insulation material | Hardened Alloy Steel | |

| Hardness | HRC 55 | |

| Slot for wrench | 6 | |

| Color | Oxide Black | |

| Thread | M50X1.5 | |

| For all ER Collet | ER40 Collets | |

| Standard | DIN6499 B | |

What,s balance collet nut?

Tool holder nut refers to a fastener of tool and collet chuck. which is installed on the tool holder. As key part fix tools, its reliable mechanical performance and excellent dynamic balance performance

The regular nut needs to be drilled on the surface or decrease its weight by other methods for removing material to correct dynamic balance after processing completion which will affect appearance.

which may lead to vibration of spindle and tool system, and thus causing abrasion of lathe and destructive accidents in serious conditions.

Balanced structure nut can ensure a balanced distribution of overall weight on the circumference in structure amend the unbalance due to uneven materials of the nut or blank defect. Excellent processing

technology makes the product balance accuracy precision higher than ordinary eccentric round nut to improve processing accuracy and the service life of the lathe.