How to maintenance your shrink fit tool holder

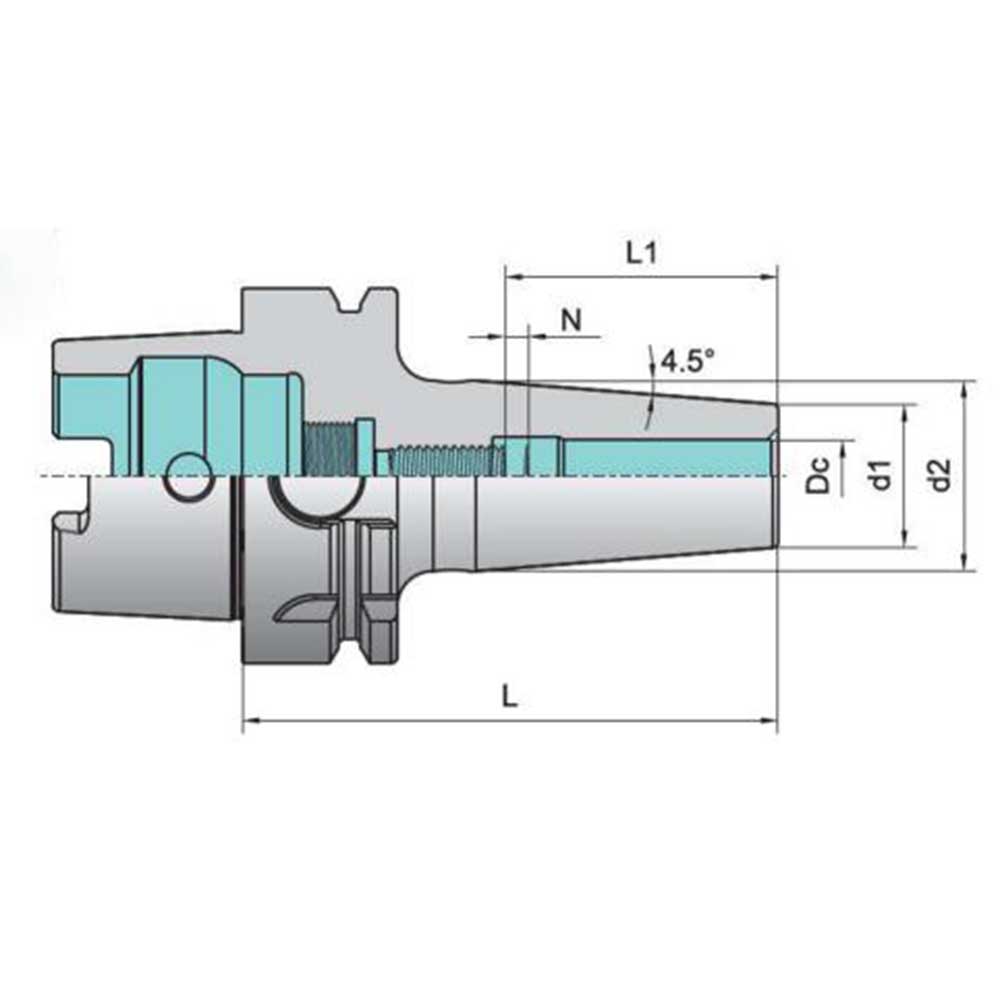

Repair and maintenance of tapered shank shrink fit tool holder

Can not be re-polished, due to the difference in manufacturing processes, re-grinding of the shrinkable shank will lead to poor accuracy of the shrinkable shank.

In addition, the position of the gauge line does not change much, which causes a malfunction of the ATC (Automatic Tool Change Device), which makes it impossible to repair.

It is recommended to replace it with a new one.

Watch out for scars and dirt

Installing the heat shrinkable tool holder with flaws, stains and dirt on the main shaft of the machine tool not only causes poor accuracy,

but also damages the main shaft of the machine tool. Always pay attention to cleaning with cotton yarn, etc.

About maintenance and care

When the heat shrinkable tool holder is not used for a long time, use an oil wash and an air gun to remove the attached cutting fluid,

and then perform rust prevention treatment. After rusting, poor accuracy and reduced tool holder life will result.

Please Use an air gun or the like to completely drain the coolant from the inside of the heat shrinkable tool holder (oil hole).

Add an appropriate amount of engine oil and blow it with an air gun again to fully protect the inside of the heat shrinkable shank.

shrink fit tool holders